Roof Insulation Compression Calculator

- Clyde Anderson

- Nov, 10, 2013

- Energy Assessment Tools

- Comments Off on Roof Insulation Compression Calculator

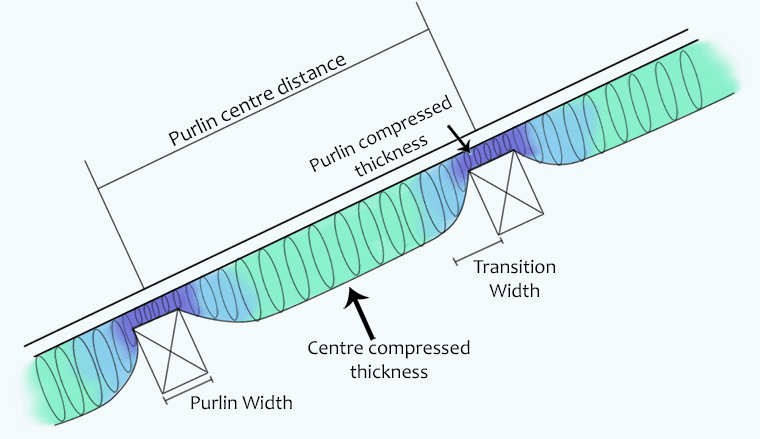

When fibre roof insulation is compressed (to fit into a tight space, squished underneath purlins or even by a retaining mesh), its R-value decreases. This change isn’t a simple linear reduction, but a complex curve that’s different for each material.

To assist in calculating the R-value of compressed roof insulation, we’re releasing for free this handy tool to crunch the insulation compression value for you. This can be used to accurately work out the thickness of installed insulation required under a building’s roof to meet the requirements of the National Construction Code or your Energy Efficiency Assessment.

Calculations come from data obtained from the AIRAH Technical Handbook (2007), AS/NZS 4859.1:2002, “The Thermal Performance of Several Australian Fibrous Insulating Materials”, Journal of Building Physics, July 1995, Volume 19, Number 1, Pages 72-88 by J.G. Symons, R.E. Clarke and J.V. Peirce, with original raw data through personal communication with Dr Robin Clarke (CSIRO) in 2012.

Whilst the calculations are accurate from the original data provided (Regression Coefficient >0.9992), the values used are for generic products that may not match any individual product currently on the market. Roof insulation performance can be affected by other factors outside the scope of this calculator such as variations in the make-up of the raw material, the individual fibre strand thickness, slight variations in the production process (including binder), packaging, handling of the product from factory to site, temperature, moisture content & installation quality. Products made on the same equipment to the same nominal specifications can vary slightly from batch to batch so results should be independently confirmed. Some finely-spun fibreglass products may have results closer to “Rockwool” data. Currently the calculator does not work for lateral compression, eg squishing insulation to fit between trusses on a ceiling, only for vertical compression. Calculation data is accurate up to ~85% compression (~60% for Loose Cellulose) & values above these are extrapolated.